On September 6, 2017, Dr. Leroy Hulsey, provided his September 2017 progress report on a project undertaken by the University of Alaska Fairbanks' (UAF's) Institute of Northern Engineering and the College of Mines. He presented his findings and conclusions during a live stream event analyzing the collapse of World Trade Center Building 7 (WTC 7). WTC 7 was a 47-story office building that fell nearly seven hours after the collapse of the World Trade Center’s Twin Towers on Sept 11, 2001. In a 2008 report, the U.S. Department of Commerce’s National Institute of Standards and Technology (NIST) attributed the collapse to office fires in the lower stories of the building. During his presentation, he muses, "The first thing I would have thought about when I got involved here is the columns obviously got really, really hot and then lost strength and we would have ended up losing the building. However, nobody seems to think that ever happened." Instead, the collapse of WTC 7 has been ascribed to fires that created enormous stresses within the building structure which caused bending, buckling and then eventually led to an eight floor cascade that led to a progressive collapse of the entire structure. Central to the NIST analysis was their assumption that the east exterior wall was fixed in space and absolutely immovable (e.g. no east exterior wall deformation). This assumption then allowed thermal expansion of the structure only to the west where it then jammed into the rest of the structure.

UAF researcher Leroy Hulsey was the project manager and was assisted by two Ph.D. graduate students at the University of Alaska Fairbanks: Feng Xiao (who now has earned his Ph.D.) and Zhili Quan. A draft report of the two-year study will be issued later this fall, followed by a six-week public comment period, with a final report scheduled for release in early 2018. This article provides a summary and transcript of his talk. The UAF project was funded by Architects & Engineers for 9/11 Truth.

Professor Hulsey reviewed the NIST analysis and expressed his findings in a presentation that could be understood by both technical and non-technical audiences. The most unexpected observation that Professor Hulsey made during his presentation was that the fire induced thermal expansion and movement of the floor was to the west of column 79. NIST had claimed that the collapse of WTC 7 was initiated by expansion and movement of the floor to the east of column 79. Professor Hulsey further explains why the visualization of NIST's incomplete finite-element analysis of the building, results in the collapse looking so lopsided. Watching Professor Hulsey's review will help the public identify numerous errors and omissions in the NIST report. Ultimately, Professor Hulsey concludes that fire did not cause the collapse of WTC 7.

Using the UAF analysis in 9/11 Truth Outreach

While professor Hulsey’s presentation is detailed and technical, it also contains elements that are easy to communicate to a wider public audience. For example, the following observations about the NIST and UAF analyses are useful when doing outreach to technical professionals and even general public and around the issues of WTC 7. Here are some of the highlights which reference the slide numbers used in the presentation.

The slides that are referenced can be downloaded from UAF download.

UAF Review of NIST Analysis

On Slide 12, Professor Hulsey posits: "So did WTC7 collapse from fires? Our study shows the fire is not the cause. I'm not going to tell you about what did it– I'm just going to tell you that it wasn't that. … This contradicts findings presented by NIST."

On Slide 13, Professor Hulsey describes the completeness of the UAF study. For example, "That concrete floor is supposed to be fastened to those steel beams and steel frames using what they call sheer connectors. In other words, those are round bolts that are actually welded to the top flange and then when you pour the concrete all becomes one. That was the concept – composite structure. But there are so many questions concerning the system that we looked at: was the floor structure composite; partially composite; non-composite. That means the slab can slide over the steel; not slide on the steel; partially slide over the steel. We looked at all those possibilities."

On Slide 17, Professor Hulsey describes the NIST analysis saying, the thermal expansion of beams K-3004 to G-3005 caused the lateral displacement of the girder framing into Column 79. What NIST is saying here is when the heated up beams got longer – because the outer wall was fixed – they are all going to move to the left. That means they moved what direction? West. And in moving so far west what happens? … This thing – girder A-2001 – bowed outward – so this moved and that moved. Note that the outer wall was fixed and immovable.

On Slides 19 and 20, Professor Hulsey goes through the NIST modeling in the area of column 79 where they used detailed representations to model the connections. The connections described on the erection drawings which instructed the construction team how they are to build the connection. He shows the details used by NIST to model the connection in the northeast corner of floors 8 to 14. In the rest of the structure, that level of modeling detail wasn't done. Outside the selected area, connections were not modeled in detail and NIST used fixed (e.g. pin) connections. He then posed two questions regarding the NIST analysis, "Do they have the same stiffness as what you were modeling here more accurately;” and then “Does it have an influence, does it change how the system is going to respond?”

On Slides 21 to 25, he then reviews the NIST animated visualizations of their progressive collapse and describes how the difference in modeling the connections (detailed vs. fixed pin) which results in one side of the building behaving so differently than the other. He then shows a side by side video of the actual collapse vs the simulated collapse, and posed the question, “Is that the same thing?” and “why is it so much different on one side than the other?”

In Slides 26 to 35, he describes the connection at column 79 where NIST claims the failure originated. He describes the construction of column 79 as an “H” beam with side plates welded on to it. He notes the dimensions of the side plates were larger than the width of the beam and this created a lip on either side of the beam, into which the girder bearing seat would have been inset. With this construction, the bearing seat that would have restrained the motion of the girder (A-2001) – that NIST said was pushed off of its seat; thus initiating the progressive collapse. NIST did not represent this lip in their model of the connection at column 79. Furthermore, NIST understated the width of the bearing seat. Professor Hulsey then states, “It is not possible to move the girder web beyond the seat as claimed by NIST.”

In Slides 36 and 37, Professor Hulsey reviews three steel members that NIST did not include in their analysis that provided lateral support to a beam that was critical to the NIST hypothesis. The NIST collapse initiation hypothesis requires that these three members be ignored. He concludes, “[Our analysis] shows that that girder does not buckle when you have them in.”

In slides 38 to 43, Professor Hulsey describes the effect of NIST neglecting the partial height web stiffeners that are shown in the erection drawings. The omission of these web stiffeners was required for the NIST collapse initiation. With them included, “[Our UAF analysis] shows that the girder will not fail with the partial height web stiffeners installed.”

NIST Floor Collapse

In slides 44 to 48, Professor Hulsey reviews the impact of the falling girder onto the floor below. This is another critical part of the NIST collapse hypothesis -- that the falling girder destroys the floors below and leaves column 79 unsupported for 8 floors. He observes that by using a modal analysis with a 0.52 Hz frequency mode, he observes that, “[The ] impact force is only 34% of the 632,000 lb. force required [to break the connections on the lower floor(s)] and thus insufficient to shear the girder bearing seat supporting welds [on the lower floors].”

Slides 51 through 53 address the issue of the characteristics of the concrete used to create the floors such as their thermal expansion characteristics and their connection to the steel beams and girders using shear studs. The presence of shear studs determines whether the floor system acts as a composite system or non-composite system. A non-composite floor system has no connections and the floor can expand independently of the beams and girders. The absence of shear studs in the NIST analysis was another omission that was required for their collapse hypothesis to proceed. Later in the presentation Professor Hulsey shows that the shear stud issue was irrelevant because of the direction of the thermal expansion -- if the exterior walls were not arbitrarily assumed to be fixed and immovable.

Slides 56 to 66 describe some technical aspects of modeling and how Professor Hulsey and his team developed and validated the use of non-linear equivalences as an alternative to detailed modeling of the connections.

The Bombshell Slides

Slides 67 to 69 are the bombshell slides. They show that the NIST assumption – that the exterior columns in the northeast corner were fixed and immovable (necessary to create the results of the thermal expansion central to NIST's progressive collapse hypothesis) was inappropriate. Without this assumption, the floor assembly thermally expanded in a direction opposite from what NIST forced their model to show. The result of allowing the structure to expand freely, resulted in minimal stress throughout the floor assembly.

Slides 77 to 81 show, the movement of floors 12 and 13 in respect to the thermal centroids. Professor Hulsey states, “So notice that our results in the SAP2000 model [shows] column 79 [moving] 1.92 inches to the right and; 1.85 inches to the right in the ABAQUS model. We did [the analysis in] two different ways and got very close answers. NIST said the movement was 5.5 inches to the left; which they revised to 6.2 inches to the left.” NIST's key assumption was completely undercut.

Conclusion

Slide 83 provides Professor Hulsey's concluding statements, “Did Building 7 collapse due to fires? No. This is based on our calculations. This contradicts the findings by the National Institute of Standards and Technology (NIST). [Our analysis provides] what I viewed as the real way it (e.g. WTC 7) actually behaved. Not what you assumed, not what you do in terms of boundary conditions – making things perhaps easier for yourself – or whatever."

Transcription and Caveat

The following transcription is a "best efforts" attempt to capture the material presented while creating a readable document. If there are any significant discrepancies between the transcription and the video, we apologize in advance. Furthermore, we invite readers to use the contact us form at the bottom of the article to inform us of their concerns. The slides that are referenced can be seen at the UAF website.

Slide 1

Thank you all for coming. I'm really honored to have the opportunity to share with you today some of the work that we've been doing over the past two years. I'm just delighted to have been asked to be part of this study that the University of Alaska Fairbanks (UAF) has been asked to do. It's a very – prestigious opportunity for us to share what we have in terms of our knowledge about this particular structure. Today we are going to be talking about a structural re-evaluation of the collapse of World Trade Center 7.

Slide 2

What makes this so interesting in many ways; this World Trade Center 7 was not struck by a plane. It was a part of the complex and yet it failed in the afternoon. So the National Institute of Standards (NIST) issued a report in 2008 which concluded that the structure collapsed because of fires causing the floors and beams to expand due to high temperatures due to fires – triggering a series of structural failures that then culminated in the total collapse of the building.

Others have argued that that fire was not the likely cause of the failure. There's all kinds of different discussions about what may or may not have happened. I want to make it real clear here today what we did and the way we approached this. This project was undertaken to answer the question: Did fire cause this building to collapse? That's our focus.

We have been very careful to let the science take us where we need to go. Never once did I want to hear or understand what the all these different possible views might be – being a very controversial subject. I tried to make sure that at the end of the day, every day that the decisions that we're making, the arguments that we're putting forth, would be defendable purely through science. That's what we believe has come out through that process. If I may back up for just a moment—throughout this process, I was the director of this research. I was fortunate to have Dr. Feng Xiao who and is now at Mississippi State (I think). He's a postdoctoral researcher there but prior to leaving here in December he was a researcher on this project as well as working on a Ph.D. under me and on our other project dealing with structural health monitoring of bridges. I'm also very honored to have Zhili Quan, a Ph.D. student here at University of Alaska Fairbanks, who's been working with me from day one on this. Without their help it would have been extremely difficult. So I'm just really honored to have that kind of talent working with me during this period.

Let me begin by saying before I get any further that this presentation is basically a September 2017 progress report. Almost everything is complete except for one thing – and that is the progressive collapse of the structure. We have been working on that for some time. We are very pleased about its progress but there's many things I want to look at yet, and so today I won’t share that with you and when we get close to that I'll show you what you might be expecting to see in the future about this – and why I'm reluctant to share it with you today. More importantly, I want to let you know that what we're going to be putting out today – since it's a progress report, not a traditional slide show where I have just bullet points, there are some slides here where I have quite a bit of prose. The idea is that this will go out and make it available for you to read – additional information if you would so choose to do that. We're going to be trying to be transparent. We welcome any questions. We're making everything that we have done available. We want to make sure that everything that we have done is scientifically tested. We have a peer review committee to make sure that we've met all those standards.

Slide 3

The methodology: I want to share that with you. We assembled first: available documents, erection drawings, etc. that were available for this project – for this building. Traditionally, I would have liked to have had the opportunity to go in and pick up all the pieces of the puzzle and put it back together like you would a typical airplane. But they did not exist and weren't available so we we've done the best we can with all available documents. Basically what we did is created AUTOCAD drawing here that we used to create a virtual geometry of this forty seven story building. Basically, in digital form you should be able to see every piece, every puzzle, every member and it should look exactly like what was used in that structure. So that's what we did. We then prepared an ABAQUS non-linear computer model for the connections and for the framing of this building and so that is a fairly sophisticated finite element program that's available that enables you to look at the detail of how something is going to respond to your set of conditions. I know that I have a mixed audience here I'll try to keep it as simple as I can. At the same time I need to share with you some pieces of complexity so those in the technical arena have an appreciation for the fact that they did look at this in a fairly sophisticated way.

There are several things here that I have a talked about. We have SAP2000, the current edition, version eighteen and ABAQUS and we use that to look at the framing. So in the plan view when we were looking at a micro structure we were using both computer programs and two different people and each one of those Ph D. students that were working for me – they were doing these individually and I was there for quality control, ensuring that everything was the same – and were we getting the same answers from two different approaches, two different people doing things. So we have quality control assurance. This is a highly complex system so I want to make sure that at the end of the day we were getting reliable results and we can test it against more than one way to do this.

So we looked at the framing at floors twelve and thirteen as they were modeled for fire damage. This is in the plan view – I’ll go through this. I realize it's not clear to you at this moment but so I'm going to give you an overview and then I’ll tell you what we did and I'm going to tell you what we did again. So SAP2000 and ABAQUS was used to study progressive collapse. We are using it to study progressive collapse – I'm not done with that yet. So that's not what I'm going to share with you. Basically what that means is that at the end of the day you look at the side of the building you see it come down. Does it look like what actually happened? And that's the place where we are with that. OK. Virtual structure was used to simulate conditions on September 11, 2001. Then we were going to share the findings with you. And then this is going to be peer-reviewed.

Slide 4

So the findings to date – part one. WTC7, World Trade Center seven: Building was not found to be collapsed by fire – that's my conclusion. That's what we found. OK. That's not consistent with the findings that were previously found by others. Findings are based on results from this ABAQUS and SAP2000 model. Part II, progressive collapse analysis are nearly complete and we're using SAP2000 and ABAQUS for evaluating. And I might point out we also used SolidWorks and other procedures to look at fire related issues and I haven't provided any information here. So I want to thank you, acknowledge and thank the funders who are the Architects and Engineers for 9/11 Truth and they are funding the University of Alaska Fairbanks and Institute of Northern Engineering and the college of Mines to do this work.

It should be pointed out that this is a non for profit corporation and the money that came to this study was out of the pockets of those professional engineers and architects. It was donated so this was something that I think is pretty significant.

Slide 5

Let's talk about the building for a moment. We have an obituary for this building: 1983 it was started ;2001 it left us. The height of the building is 47 stories and is an Emory Roth and Son’s design with the red granite facade -- is what it looked like.

Geometry was a trapezoidal footprint which we'll see in a moment. Six hundred ten feet tall – kind of gives you an idea about how tall it is; three hundred thirty feet long and hundred forty feet wide. The construction began in 1983 and it was opened in May 1987. The foundation of the building, a skyscraper, was built on caissons. It was actually built above and through a 1967 Con Edison substation that was designed to carry a future twenty five story building. However when this building came along, there were not enough caissons there so they added caissons and they went to the proposed support system -- so this was the foundation for this building.

The structure. Basically here's the concept. The structure as a system of gravity columns, transfer trusses and girders that were located between floors five and seven. I'll show you that in a moment to give you clarity about that. The fifth floor functioned as a structural diaphragm providing lateral stability and distribution of loads between the new and old caissons. So imagine it's down to the bottom at the fifth floor -- you have this irregular conditions going on and that structure portion took care of that. Above the seventh floor the building structure was a typical tube frame design with columns in the core and on the perimeter and lateral loads were to be resisted by perimeter moment frames.

Slide 6

Let's just take a moment – and take a breath of fresh air. Remind ourselves that we're now looking at history. And in this history lesson we are seeing that WTC complex – the World Trade Center complex that disappeared in 2001. So here's the Twin Towers, WTC1 and WTC2 and over here is WTC7. That kinda brick looking facade that I was telling you about earlier—kind of a beautiful building. Located about three hundred fifty feet north of the World Trade Center you know was about what three hundred meters or a little over one hundred yards away. World Trade Center complex elevation was what we're looking at here that's what it looked like prior to September eleventh.

Slide 7

In the plan view, to give you a different perspective, here's the north arrow – so the northeast corner is where we’re going to spend our life in the next hour – in that northeast corner.

That's the farthest away from that arrow pointing to that building. That's the plan view. This study is really about why this building came down – was not struck by a plane, yet collapsed. That's almost an overwhelming thought if you stop and think about it for a moment.

Slide 8

If you look at it from an elevation view and try to take a look at the very sides of this building – and what it may have looked like. Here's the north elevation. So when I talk about the north elevation I'm really talking about this elevation here the width. Notice that it is wider, trapezoidally, than this south elevation. So the building is not symmetric. So there are all kinds of issues, but this makes it really interesting.

Slide 9

So here is that width. So here is the South – if you notice it's not as wide and then here is the West elevation and the east elevation.

Now within that context here is floor thirteen. I put that there because we're going to spend a lot of time there – so you'll have some understanding of what the heck's going on in an area. Here are these perimeter trusses I was telling you about. Those are at floors 5 and 7 and floors 24 and 22. Those trusses are resisting lateral loads. In the plan view (at bottom) you see A-C-D and so forth for the building in plan view we're looking at. Down below is a Con Edison substation, shipping and all the things going on down here. So that's what it's built on – that's what it looks like – that's what we're dealing with. Way more complex and that's the perimeter view. That's not what it looks like in the internal view.

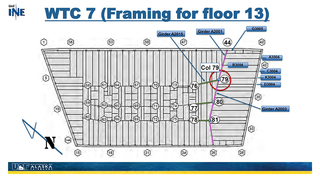

Slide 9

Slide 9: WTC7 (Framing for floor 13)Here’s the internal view. So all of a sudden (showing a new slide) we see that there is plan view, there is a frame, there is a structural system everywhere. These little hexagons are the columns. They are supporting vertical loads. The other things are either girders or beams. So the main load carrying members like this, right here that's a girder. These things framing into it are beams. So this is girder A-2001 that we're going to talk about. We’re going to talk about girder A-2002. This is column 79 where we're going to spend quite a bit of time this afternoon having a conversation.

Slide 9: WTC7 (Framing for floor 13)Here’s the internal view. So all of a sudden (showing a new slide) we see that there is plan view, there is a frame, there is a structural system everywhere. These little hexagons are the columns. They are supporting vertical loads. The other things are either girders or beams. So the main load carrying members like this, right here that's a girder. These things framing into it are beams. So this is girder A-2001 that we're going to talk about. We’re going to talk about girder A-2002. This is column 79 where we're going to spend quite a bit of time this afternoon having a conversation.

And this is a beam on the exterior G-3005. The reason it's important is because it has to do with the lateral bracing of this whole system. I turned these things in circles because – again they could have been hexagons, but I wanted to bring them out so we could pay attention to them. And that's column 44; column 79; column 80; column 81; and then this is column 76; So our life in this plan view is going to be in the area. Because column 79 – just to give you a snapshot of where we're heading – column 79 is basically what they said failed – to bring this building down. So we're going to go there and take a look at it and we're going to look at it intensively.

Slide 10

So where were these crazy fires? You know when they started – keep in mind – I should've had a slide here, I suppose I thought I did, about when World Trade Center 1 and 2 actually got hit – that was in the morning. Then later in the afternoon World Trade Center 7 came down – hours later. They had fires that were reported, having come from World Trade Center 1, coming through the windows and so forth. And they were on the floor 7 to 9; 11 to 14; 19, 22, 29 and 30 – and this was after (e.g. based on) the NIST report where they reported those fires.

Slide 11

One hour before collapse, it's reported that there weren't any fires on floors 3, 5 and 7 so there were fires up in here. Question is … you have to ask yourself a lot of questions, and we don't always have answers. So where’s the combustibility – this is a steel structure so what actually was going on in this building? And we'll get there shortly.

Slide 12

So did WTC7 collapse from fires? Our study shows the fire is not the cause. I'm not going to tell you about what did it– I'm just going to tell you that it wasn't that. What I am going to do is show, maybe not today so much, but a little bit later when we look at progressive collapse is this – tell you what had to happen for this thing to come down – that is what we will be able to tell you. This contradicts findings presented by NIST, Our presentation will address this issue. We will discuss the NIST approach and our approach and findings. So what's next after today? We have a progressive collapse analysis that are ongoing and when we finish that, very soon, I will make that available to everybody so you can see it. I wanted to have that today but I'm not going to give you something that I have to change later and thinking “oh my gosh I rushed it” and it was wrong. I'm not going to do that. I would rather give you something that you can feel comfortable with when we're done.

Slide 13

So the NIST assumptions and claims that were used in the UAF analysis: Let me give you a snapshot here of where I'm going with this. NIST had some assumptions and claims that they used to get their report to come to the conclusion that that they did. So what we've done is several things, and I meant to put this on a slide -- there weren't enough nights in the day to make this happen so this one slide I'm going to share with you verbally.

So basically the NIST assumptions I'm laying out here. We then did several things. Number one is that we looked at – could that have actually occurred if we use their assumptions. So that's one thing we did.

The other thing we did is we simulated exactly what they did simulate to see if we came in same conclusion. And we did that by several things. Number one is that this World Trade Center building is a steel frame structure with steel beams and steel girders. Does anyone have an idea what I'm talking about when I say those things? It's basically supporting a concrete floor.

That concrete floor is supposed to be fastened to those steel beams and steel frames using what they call sheer connectors – in other words those around round bolts that are actually welded to the top flange and then when you pour the concrete so that it all becomes one.

That was the concept – composite structure. But there are so many questions concerning the system. We look at it from composite; partially composite; non composite. That means the slab can slide over the steel; not slide on the steel; partially slide over the steel. We looked at all those possibilities. We looked at whether the fires were underneath and burning up the ceiling. Or looking at burning down through the floor. I mean all those issues were examined.

Here's their assumptions. The beam temperatures reached six hundred degrees C. The girder temperatures A-2001 to A-2015 reached five hundred degrees C.

So what am I talking about here. So let me go back for a moment and share with you A-2001 is that girder. A-2015 is huge right here. So these girders are what we're talking about in that temperature range. The beams didn't get that hot. So if we take a look at the beams, they reach 500 degrees C and the columns temperatures only reached 300 degrees C. Now that's significant, because there's a point in time and I'll show you a moment where-by there is a point where the steel begins to decrease in strength and modest decreases when you reach a certain elevated temperature. The first thing I would have thought about when I got involved here is, OK, the columns obviously got really, really hot and then lost strength and we would have ended up losing the building.

However, nobody seems to think that ever happened.

And furthermore there weren’t a lot of combustibles in there. So no east exterior wall deformation occurred due to an expansion of beams – that's their assumption. In K-3004; C-3004 etc. where is that at? I wanted to give you a heads up on what I'm talking about. [Back to showing slide 9] That's along this line. Those are the lines of these beams right here – you see these beams – they're going into these girders – they're framing them. Am I making myself clear? So in plan view, I've got a beam going from this outer edge to that girder and those are the beams and those are the numbers, 3004 and so forth, that we're talking about. Now moving on. With that idea in mind we've got all that beautiful thing captured in our minds. We're ready to go.

[Continues with Slide 13 – NIST Assumptions] So there were no shear studs installed on the building girders. I’m going to take you through where we disagree in a lot of areas. Shear studs on beams K-3004; S-3004; B-3004, A-3004 and G-3005 they are saying that the shear studs on these beams were broken.

The bolts fastening A-2001 to its seat at columns 44 and 79 were broken. That is significant. So let's go back here [Back to showing slide 9] – here's column 44 and there is column 79. They are saying the connection of this girder, to those beams, to those columns, the seat connection did not function during that period and therefore lost lateral support and produced a problem.

Slide 14: floor framing and column layoutSo they lost those supports so that means those two columns no longer have lateral support at that level and did they possibly have a problem later. The floor loading was 88 pounds per square foot. The NIST computer model results were based on exterior columns being fixed in every direction. That's kind of a significant thought.

Slide 14: floor framing and column layoutSo they lost those supports so that means those two columns no longer have lateral support at that level and did they possibly have a problem later. The floor loading was 88 pounds per square foot. The NIST computer model results were based on exterior columns being fixed in every direction. That's kind of a significant thought.

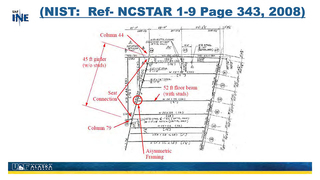

Slide 14

So now looking at their plans –this stuff – this came out of the NIST report on page 343 (ref. 2008) and so this gives you the geometry. That's a forty four foot link from column 44 to 79. Forty four foot, that's the girder length. It's longer than this for sure. You see? That's not small – this is a huge building. Six hundred feet across. So here is fifty seven feet here – fifty four feet across. This is our exterior wall. I'm in the northeast corner of this building – is that is that clear to everybody. That here we are in that trapezoid world. Notice that there's actually symmetric framing. These beams are fifty two feet long that's not small. I mean where in the world do you see that kind of stuff?

Slide 15

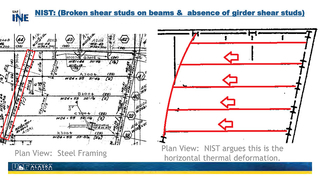

Slide 15: NIST: (Broken shear studs on beams & absence of girder shear studs)So in their view, by taking a heat model – taking and putting fire on it and then subjecting their model their finite-element model to an increase in temperature they got a thermal expansion. The thermal expansion looks like this. So that actually is this girder, right here, A-2001. It expanded and they said it pushed off this bearing seat and thereby they lost support. Then these cascaded downward. So that's basically what we're talking about here.

Slide 15: NIST: (Broken shear studs on beams & absence of girder shear studs)So in their view, by taking a heat model – taking and putting fire on it and then subjecting their model their finite-element model to an increase in temperature they got a thermal expansion. The thermal expansion looks like this. So that actually is this girder, right here, A-2001. It expanded and they said it pushed off this bearing seat and thereby they lost support. Then these cascaded downward. So that's basically what we're talking about here.

Slide 16

There's the girder I'm talking about. There's that exterior, and here are the lateral supports for this beam system through here.

Slide 17

So what were their conclusions? First of all fire-induced weakening of critical columns did not cause the WTC 7 to collapse – didn't get hot enough. They are saying that 300 degrees is not hot enough. Temperature in column 79 is below 200 degrees C. I think that's true – I might have to look that up as a reference again – but I'm pretty sure that's about what it was. The movement along the x axis of beams K-3004 to K-3005 was caused by thermal expansion. Lateral displacement of the girder framing into Column 79 was result of thermal expansion of the beams framing into the girder. [Back to Slide 16]

All we're saying here is: when heated up they got longer. This was fixed so they are all going to move to the left. That means they moved what direction? West. And in moving so far west what happens? Now they're going to try to move – and is or enough space to hold them in place. That's what their argument is, right? That's key right there.

And that's what it looked like. Bang-bang-bang. This thing bowed outward – so this moved and that moved.

Slide 18

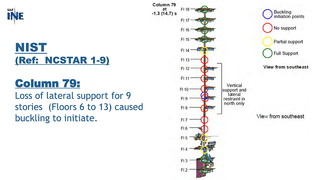

Slide 18: Column 79: Loss of lateral support for 9 stories (Floors 6 to 13) caused buckling to initiate.This is the cascade issue that they said. The buckling initiated here at this place right here – at floor 9. Then all these issues mean that they lost lateral support of that column. This column 79 by the way – the one I'm talking about. The one we've been focusing on. This column doesn’t have any lateral support and because of that link it can not take nearly as much load as it was designed for. And so consequently the vertical support of lateral restraint in the north only and so therefore there's a huge problem. And then a full lateral support up here and then there's partial lateral support down below.

Slide 18: Column 79: Loss of lateral support for 9 stories (Floors 6 to 13) caused buckling to initiate.This is the cascade issue that they said. The buckling initiated here at this place right here – at floor 9. Then all these issues mean that they lost lateral support of that column. This column 79 by the way – the one I'm talking about. The one we've been focusing on. This column doesn’t have any lateral support and because of that link it can not take nearly as much load as it was designed for. And so consequently the vertical support of lateral restraint in the north only and so therefore there's a huge problem. And then a full lateral support up here and then there's partial lateral support down below.

So that's down here in the in the bottom, down here to very bottom, in the Con-Edison area that those are all laterally supported. But between this zone, they all went away. So the loss of lateral support for nine stories from six to thirteen caused buckling to initiate, which means you lost it. Is that clear? Am I clear about what I'm saying here?

Slide 19

Now, let's take a look at their model for a moment. Their model is this: looking at a partial of that trapezoid down here—we're seeing a partial of it. This is the northeast corner. There's column 79 and in that blue – it's kind of significant that blue.

Every place a beam and a girder come together – a column to a girder goes together – a beam does all these kinds of things – there's a connection. A connection that's on the drawings – that says here's how you will build it. Bolt them together – you make it do whatever you want them to do and that's the way it was supposed to be built. Remember that the north arrow is here; This is the west side; the east side is to my right; This is after NIST area connections were modeled on floors 8 to 14 and that's what is in the blue area. Over here that wasn't done. So there's column 79. Here's the area outside of the thing, so now let's take a look.

Slide 20

Slide 20: NIST Model (NIST, 2004)Outside the selected area, connections failures were not modeled. NIST used fixed or pin connections. So automatically you have to ask yourself the question. Do they have the same stiffness? As what you were modeling here more accurately. The next corresponding question is: Does it have an influence? Does it change how the system is going to respond? And so the connections were not model for the exterior frame and the columns themselves were treated as fixed.

Slide 20: NIST Model (NIST, 2004)Outside the selected area, connections failures were not modeled. NIST used fixed or pin connections. So automatically you have to ask yourself the question. Do they have the same stiffness? As what you were modeling here more accurately. The next corresponding question is: Does it have an influence? Does it change how the system is going to respond? And so the connections were not model for the exterior frame and the columns themselves were treated as fixed.

Slide 21

So also in the NIST documentation page 525 (2008), a girder was considered to have lost vertical support when its web was no longer supported by the bearing seat. That means the girder.

That means if there was a loss of bearing support on A-2001 coming into the column 79. Then it's lost. The bearing seat at column 79 was 11 inches wide. That when the girder at column 79 had been pushed laterally at least five and a half inches the web over – it was no longer supported by that bearing seat. NIST changed that 5.5 inches to 6.25 inches when it was shown that the seat was actually twelve inches wide. So that's just kind of something to think about. Why did that happen? And that was later.

Slide 22

Some of the NIST results are the following:

Slide 23

Slide 23: Comparison of NIST progressive collapse model vs. actual videoAnd pardon me, I hope I'm not boring you, but this is a passion for me. Let's just take a look at what actually happened. Here is the NIST model – and remember those connections. We're looking at this from […] the North face of the building. So here's a penthouse up here. You’re going to see two different situations here because of the connections issue. Now let’s see what this does – this the real building. So here's their model – this is their progressive collapse. I'm not going to show you ours yet. Here it is. [video of simulation vs. actual collapse plays]. Take a look at the failure as it actually did occur that day.

Slide 23: Comparison of NIST progressive collapse model vs. actual videoAnd pardon me, I hope I'm not boring you, but this is a passion for me. Let's just take a look at what actually happened. Here is the NIST model – and remember those connections. We're looking at this from […] the North face of the building. So here's a penthouse up here. You’re going to see two different situations here because of the connections issue. Now let’s see what this does – this the real building. So here's their model – this is their progressive collapse. I'm not going to show you ours yet. Here it is. [video of simulation vs. actual collapse plays]. Take a look at the failure as it actually did occur that day.

So one has to ask themselves: Is that the same thing? Is that the same building? So it looks like it behaves in an interesting sort of way. So anyway, let's go on.

Slide 24

Here's the NIST model that we were just looking at. This is the other side, you see, its flipped. I'm showing you where that modeling was actually done. This is columns 76, 78 and column 79 – was in here. So they were looking at the finite element progressive model that they were using to look at that.

Slide 25

I suppose we could even look at from a different perspective, and there it is again. This is what they’re doing.

You have to ask yourself the question though, why is it so much different on one side than the other? Do you see what I’m saying? Because of some damage that came in from debris falling through the windows, they are accounting for some of that stuff.

Slide 26

So let's talk about UAF for a moment – Analysis of the NIST Collapse Initiation Hypothesis and Propagation Claims is what we've about to embark upon. How valid is some of the stuff? From a science point of view.

Slide 27

So the UAF analysis of the NIST collapse initiation hypothesis and propagation – we created a solid model in ABAQUS of structural members in the northeast corner of the 13th floor of WTC 7. A finite element analysis was then performed to replicate the results claimed in the NIST WTC 7 report that girder A-2001 was pushed or rocked off its seats at columns 44 and 79 to initiate the collapse of the building.

So one might argue that if those things didn't happen, would the building have collapsed?

Slide 28

OK so here we go. This is the area I’m dealing with. Right in here there is column 79. Here’s that girder A-2001- between columns 44 and 79. The question then becomes, how does it behave? What we're going to do is create part of a finite element model, and we're going to be really conservative. We're going to force things that happen that's worse than the real world. OK, and in so doing, if we can't force failure – then it couldn’t have happened. Are you with me on this point? So that being said, we're going to fix the ends; we're going to force movement through girder A-2015 by heating it up. This here is going to be heated up; these beams are going to get heated up; and they're going to be fixed in the other direction. So we're pushing it in each direction to make a matters really the worst possible.

Slide 29

This is what that model looks like. This is the floor system. We don't have the entire floor system yet We do, by the way, have the entire floor system. But for this analysis; to evaluate what's going on right here: column 79, that girder – in this condition we're looking at what we need to do – and that is look at the boundary conditions to force that condition to be absolutely the worst possible. OK, we did that.

So this is the beginning -- you notice everything is zero – the stresses are all zero – we haven't put the temperature on it yet.

Slide 30

Slide 30: Section of Column 79 (showing side plates)This is the column that we're talking about. This column 79. This is real significant, by the way. Because how column 79 is built – if you look at it. Do you know what I'm talking about when I say a W shape?

Slide 30: Section of Column 79 (showing side plates)This is the column that we're talking about. This column 79. This is real significant, by the way. Because how column 79 is built – if you look at it. Do you know what I'm talking about when I say a W shape?

W shape looks like an H – and that's what we're looking at right here. That's what that column was made of. It is a W14x730 standard structure shape. What that means is that it is fourteen inches deep and weighs seven hundred thirty pounds per linear foot. That's a chunk of change. Now within that context though, what they did, they built side plates on it and they closed that box. They closed it so it had structural integrity to resist a twist. Significant.

But those edges, 2” x 26” build up, means that there is a lip on each side of this and they are literally going to put on that flange, the bearing plate (between the lips). That column stays vertical but we're going to put a bearing plate in here.

Slide 31

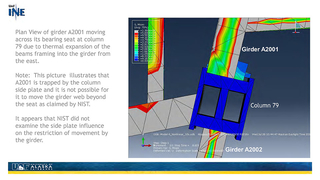

So that's what it starts to look like. We're looking at right now – plan view – A-2001 going over to Column 44. And there's a connection to column 79. See that lip right here—those lips. Got it? So if this thing starts moving and it's getting shoved – and if it's just getting shoved to the west which is to my left – and probably your left too. Then it can't get past that thing. Unless something happens or breaks, right? That make sense?

Slide 32

Slide 32: Plan view of girder A-2001 impinged upon side plate lipsThere it got shoved. So plan view of A-2001 moving across its bearing seat at column 79 due to thermal expansion of the beams framing into the girder from the east is here – and it gets shoved. Note that picture illustrates that A-2001 is trapped by that column side plate. It is not possible to move the girder web beyond the seat as claimed by NIST. They’re saying it got shoved off and fell down. The fact of the matter is they didn't have the side plates on. They weren’t there in their model. So they wouldn’t have found that. But yet they did exist in the structure – in reality. It appears that NIST did not examine the side plate influence on the restriction of movement by that girder.

Slide 32: Plan view of girder A-2001 impinged upon side plate lipsThere it got shoved. So plan view of A-2001 moving across its bearing seat at column 79 due to thermal expansion of the beams framing into the girder from the east is here – and it gets shoved. Note that picture illustrates that A-2001 is trapped by that column side plate. It is not possible to move the girder web beyond the seat as claimed by NIST. They’re saying it got shoved off and fell down. The fact of the matter is they didn't have the side plates on. They weren’t there in their model. So they wouldn’t have found that. But yet they did exist in the structure – in reality. It appears that NIST did not examine the side plate influence on the restriction of movement by that girder.

Slide 33

So now let's take a look at what else we looked at. And this is just part of the puzzle because we've been playing this game for two years. So this is just a few weeks of stuff. The model shows the influence of the thermal expansion at the north east corner of floor 13. Here we are. There is column 79; column 44; and there's the northeast corner and here are the beams framing in to that girder system. So when A-2001 is trapped behind a side plate of column 79, these beams (K3004 and D3004) begin to buckle. In other words, they can’t go anywhere. So its heating up – it's pushing and they can't stand the amount of load, axially, that is being imposed on them. So they begin to try to displace out of the way to relieve them from their states of stress. Are you following what I’m saying here?

Slide 34

So fundamentally, that happened. So this is out of the NIST WTC 7 report, Figure 8-22, which is showing basically the concrete slab, metal deck, all that kind of stuff. Exterior columns out here. And this is basically column 79, column 44 and how that column is – and the girder here – and so forth.

Slide 35

And here's what begins to happen on the exterior columns according to their study. And so they did not have the side plates in there.

Slide 36

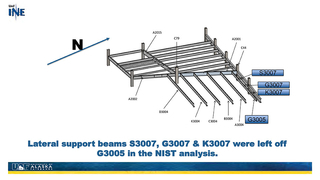

Slide 36: Lateral support beams S3007, G3007 & K3007 were left off G3005 in the NIST analysis.So let's treat for a moment the lateral support beams S-3007 – and so forth. So here we are in this area – right here. See these little beams in there? They play a role, and that means that they provide lateral support for that beam. They provide lateral support for that beam – also for that exterior. So they are forcing them to act together not as individual. So if that is actually got out of hand you have a lot more capability from a lateral torsional buckling point of view – or an axial load point of view—and so the lateral supports on this were left off. In G-3005 of this beam they were left off – they were left off – yet they're there. So that means that something could happen – and there it is.

Slide 36: Lateral support beams S3007, G3007 & K3007 were left off G3005 in the NIST analysis.So let's treat for a moment the lateral support beams S-3007 – and so forth. So here we are in this area – right here. See these little beams in there? They play a role, and that means that they provide lateral support for that beam. They provide lateral support for that beam – also for that exterior. So they are forcing them to act together not as individual. So if that is actually got out of hand you have a lot more capability from a lateral torsional buckling point of view – or an axial load point of view—and so the lateral supports on this were left off. In G-3005 of this beam they were left off – they were left off – yet they're there. So that means that something could happen – and there it is.

Slide 37

So UAF analysis showing beam G-3005 does buckle when lateral support beams G-3007, K-3007, and S-3007, spanning to it from the north exterior wall, are not installed. So if those are not installed, it’s going to buckle. So UAF analysis also shows that that girder does not buckle when you have them in.

There's a huge difference between those two dots – and what that might mean to the behavior of the system – spanning to it from the north exterior wall – as we see here. Is everybody getting a mental picture of this building? You should almost be getting an intimate view of what we've been living with – in this picture.

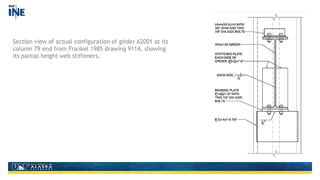

Slide 39

Slide 39: Section view of actual configuration of girder A2001 at its column 79 end from Frankel 1985 drawing 9114, showing its partial height web stiffeners.Let's take a moment, to take a breath of air. Section view of actual configuration of girder A-2001 at its column 79 end from Frankel 1985 drawing 9114, showing there are partial height web stiffeners in here.

Slide 39: Section view of actual configuration of girder A2001 at its column 79 end from Frankel 1985 drawing 9114, showing its partial height web stiffeners.Let's take a moment, to take a breath of air. Section view of actual configuration of girder A-2001 at its column 79 end from Frankel 1985 drawing 9114, showing there are partial height web stiffeners in here.

Now folks let me just absolutely tell you; this is critical. Those stiffeners prevent this buckle, this web from buckling. But more than that, it prevents these flanges from getting over stresses and eventually having a problem. If they are there. But NIST did not include them.

Slide 40

Partial height web stiffeners are missing. That means there are some issues here that literally affects the behavior of the system.

Slide 41

So figure 8-23, finite analysis model from the NIST WTC 7 report – note the partial web stiffeners are missing. So the behavior of this interaction between column 79 and A-2001; column 44; the beams to the girder; the moving of the girder on the base plate. Now remember they didn't have the side plates; Didn’t have the stiffeners and all of those things are going to give you a huge added resistance to anything going on here. And in spite of that fact – I'm going to share with you some other things that makes it quite interesting.

Slide 42

So here we go. Here’s what happens if you don't have any side plates.

So the analysis was performed forcing girder A-2001 web beyond its bearing seat by removing the column side plate and increasing the coefficient of thermal expansion of the beams framing into the girder by 40%. So we can get that kind of movement – that is not true, we just did it – just to see what would happen. Without the increase in the coefficient of thermal expansion the web would not have moved sufficiently to get it off the bearing seat. We wanted to see it we could make it move.

That's what we get. That's at column 79; that's A-2001. Is that clear? Everyone got a mental picture of what's happening?

Slide 43

The UAF analysis shows that the girder will not fail with the partial height web stiffeners installed. The small area of high stress is not in the load path – right here; right there – is not in the load path and is due to the tip of the girder being compressed against the flange of column 79. This is not a structural concern. It is a fact that there was some over-stress there. It's not going to cause the building to come down.

Slide 44

So we also conducted a modal analysis showing 0.52 Hz frequency mode of the falling beam and girder assembly which was needed to calculate the combined stiffness of the contacting structural members and the subsequent impact load on the girder below on the 12th floor.

So here we are on the 13th floor – it falls, drops off of that base plate. Drops down; beams go; girder goes; concrete goes—all that stuff happens. You’re gonna have stiffness involved. You’re gonna have F=MA involved. You got to have those conditions and so we looked at that. NIST & ARUP claimed that the falling beam & girder assembly from floor 13 impacted and broke through floor 12 resulting in an 8 floor cascade. So, based on the natural frequency of the stiffness of the beams can be calculated and the amount of deflection and load can be examined. This establishes whether these phenomena could physically occur.

Slides 45, 46 and 47

I want to share this with you. I'm not going to spend any time on it – but those calculations are in the following pages. OK so we did that to examine that issue. That's where they are. You can go at night, while you're relaxing, you can read these. I'm not going to read them for you.

Slide 48

So we had this 215,211 lb. impact force is only 34% of the 632,000 lb. force required and thus insufficient to shear the girder bearing seat support welds. The northeast corner of floor 12 would not have collapsed if a girder at floor 13 came off its seat. That’s basically what we are saying. Thus the ARUP analysis does not show a basis for propagation, even if the girder were to fall off its seat at column 79. These findings illustrate that ARUP’s explanation is actually invalid. That's another group by the way so there's more than one group involved.

Slides 49 and 50

Weidlinger Associates report – this information is going to be presented following this. So here that is, if you want to read it. Originally, I had a change to this and looks like that change didn’t get made. But I broke this out.

Slide 51

Let's talk now about our approach—which is looking at things from a different perspective.

There was a 5 ½ inch movement at the girder bearing support at column 79 according to the NIST. Issues that led to that 5 ½ inch movement was non-composite at the main girders. What do I mean by that? You have concrete floor slabs – and on those concrete floor slabs you have to decide how you want to build them. Are you going to build it with sheer connectors to the flanges and make it act as a system, or are you going to leave them so that they can slide. So I looked at it both ways. What if it slides? So “sliding,” so lubricated between those flanges and that concrete there's no resistance to movement.

What if there's friction between them. We looked at that. What if it is partially composite, what if it is totally composite? We've neglected thermal expansion of the concrete slab. Separated connection modelling. Web flange stiffeners were looked at – all those issues are going on there.

Slide 52

So our approach was to say, OK, let's take a structural modeling approach, look at two programs: ABAQUS and SAP2000.

I established a quality control program by which we have two researchers. There was Zhili and Feng. Each one of them doing the same thing much of the time. Then challenging each other, with me there as a referee, to make sure that what we got out of it was going to be useful – and if we didn't agree we had we had dialogue and we would not be able to try to find ways of “what's going on here,” “what's wrong.” Until the point that, scientifically, we had we were able to justify every step in the way. It takes longer but it's a value to make sure you have good stuff. So in ABAQUS we developed non-linear springs-for-connections structures. It means that if you have these members bolted together and things move and it moves fairly significantly then it's probably not a linear curve. It's probably not a straight line. It is probably going to deform non-linearly and may never come back the way it used to be.

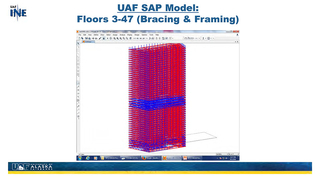

So we're looking at a non-linear response. We looked at composite, partially composite and non-composite. We looked at floors 12 and 13. We looked at thermal expansion. SAP2000 we looked at floors 12 and 13, again and floors 3 to 47. Here's what we did do though, we used the NIST fire models to look at this. Then we looked at heat transfer using SOLIDWORKS and we also used ABAQUS to do that.

Slide 53

The steel framing connections to columns beams and girders were considered throughout the entire floor – not just part of it, by the way, but all of it. Non-linear springs on all stories is something we haven't finished yet – but we've looked at.

Sub-structuring frames and concrete floor were used to minimize computer time. It's my understanding that some of these computer models were taking up weeks to run. I went to a sub-structuring system where we could run in less than an hour, maybe half an hour, maybe even less than that. They ran really fast because I took out all the complexities and replaced them with equivalences. Then if we wanted to know what was going on with the no equivalents, we put that stuff into those – so we could save huge amounts of computer time.

Heat transfer was studied. We looked at the floor tile over concrete with weld wire fabric, stay in place forms, flutes. So these were or stay in place forms, so there were flutes. What does that mean … Imagine if you take a straight line and you're dropping like a little square hole, you say, and it's long and that space is a space where they don't put in concrete. It’s an open space. Saves concrete, still gives strength and that's flutes.

So the question now became: fire protection versus no fire protection. We came up to what does that mean in terms of fire; what does it mean? Is there an issue there? So we look at that as well. We looked at equivalent concrete conductivity in expansion, accounting for Dolemite aggregate, weld wire fabric and geometry for the section. What am I talking about here? We went back to New York and we said , what kind of aggregate are you using when you built this. We tried to be sure that we knew what aggregate. The aggregate has a huge effect on the thermal conductivity and the thermal expansion of the concrete.

It's seventy five percent of the product – so therefore we need to know what it's going to be. I had written a paper on this subject some years before and had a pretty good understanding of that.

Slides 54 and 55

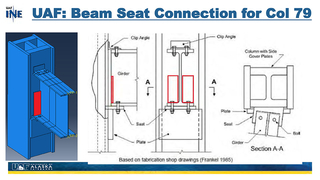

Slide 55: UAF's beam seat connection for column 79So this again is a NIST seat connection at column 79, that they did. But they didn't consider those stiffeners. So here's the way we begin to model the actual system the way it went together.

Slide 55: UAF's beam seat connection for column 79So this again is a NIST seat connection at column 79, that they did. But they didn't consider those stiffeners. So here's the way we begin to model the actual system the way it went together.

Here are our side plates – notice that they are there. Here is the girder coming in. And here's a partial height stiffeners.

And so therein lies – they actually were there – and we begin to model them from a computer program to digital so we knew how this thing is going to behave when you put it together.

Slide 57

Here's what that floor system actually looks like. By the way these are elevator shafts. Over in here is column 79.

There is column 44. There's the exterior of that floor. There's a whole system. That's an ABAQUS model by the way, that we're looking at.

Slide 59

UAF sample connection response. Basically I've taken every one of these connectors now. We've identified this and called it an S.T.C. That's our name. S.T.C. What does it look like? It looks like this. That's a connection type. And we plotted the shear load versus displacement on it. So we can always go in and put that spring where that's that – and get a response that will be equivalent to if we have used the complication – all that complication is there anyway. So we threw it away. Then we replaced it with an equivalent to save time.

Slides 60, 61, 62, 63 and 64

Then we looked at the Fin (F) connection using the same idea. I'm going to not waste your time, that's how it was put together. There how it's actually put together mathematically. That's what starts looking like as a behavioral system. Then we plotted a curve for it and we have a spring system. Same idea and so forth.

Slides 65 and 66

So that is what it begins to look like. We've basically put a load and plot its behavior – and from that we can then put the equivalent into it.

Slide 67

Slide 67: UAF's SAP2000 Model: floors 3-47 (bracing & framing)This is a simple model of floors 3 to 47 from SAP2000. That's what we're using actually using to look at progressive collapses with.

Slide 67: UAF's SAP2000 Model: floors 3-47 (bracing & framing)This is a simple model of floors 3 to 47 from SAP2000. That's what we're using actually using to look at progressive collapses with.

Slide 68

So let's take a quick look at the materials that went into this thing. I won't bore you too much – just a little bit. So the material properties: steel were ASTM A572 with a yield of 50 ksi. Thermal conductivity of the steel was 35 BTU/(hr-ft-F). Here is the thermal strain value 7.78e-06 in/in/°F (value used by NIST) and density of 490 pcf. We also had some ASTM A36 steels in here, but I’m not showing you all of it.

Concrete’s 28 day compressive strength was 3,500 psi. Density was 145 pcf; Dolomite aggregate – we got a thermal conductivity for it; We got equivalent thermal conductivity that we will be using and thermal expansion.

So that's the kind of stuff that actually made up the model to simulate what we thought the building was going to be.

Slide 69

We took and fixed the exterior of columns – this wall line here – as did NIST and we subjected it to the heat up model and we got very similar results. Here we have the connections as they truly are.

All of this system throughout this entire floor system, how that actually was built. Then we heat it up. With my heating it up and we have a dead load here about 5,142 kips. We have a movement of that section right there – of almost two inches -- but not west – went east.

Totally different. The floor moved east at column 79, not west. And by the way, they moved together. They didn’t move separately.

Slides 70 and 71

So here's the material response versus temperature. Here's that column 79 column capacity curve as a function of temperature. You can see that even if you drop down into here you don't get much change. Column 79 at 392 degrees Fahrenheit. So this is load capacity versus the effective length for these various temperatures.

So this is 1,832 degrees Fahrenheit, I think you can see it to make a difference – huge amount – how much difference in the capacity of that thing.

Slide 72, 73 and 74

So let's talk about the fires that we actually put in this building.

Here's what they were on floor 13. There's that whole area at six P.M. And there's the fire. That came from the NIST models and we used them – at this point. Same here at floor twelve.

Slide 75

UAF ABAQUS structural movements.

Slide 76

Just kind of wanted to share with you this is the model we're talking about.

Slide 77

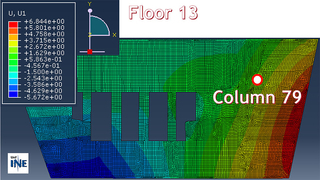

This is floor thirteen.

Slide 77: Horizontal displacement due to thermal expansion of floor 13 at col 79.

Slide 77: Horizontal displacement due to thermal expansion of floor 13 at col 79.

Slide 78

This is the column 79 at floor 13—1.85 inches to the right. That means east. Doesn't mean west. So this whole thing moved. I'll show you a different picture, hopefully in a moment.

Slide 79

So this is all the stuff to the east of this.

Slide 80

So you can begin to see the displacements. If you start looking at (the scale) -0.5 inches – now where is the zero at (-5.783-01 inches) – it's over here somewhere (see the light green colors in the legend). There’s column 79 –so it's moving with respect to this area over here.

It's not moving with respect to this. It's not moving with respect to that. It's moving this way or that way with respect to what we call the thermal centroid. Which is your stiffer point. So you can so basically get a center of stiffness by which this thing's behaving – and that's what's happening here.

Slide 81

So notice that our results in the SAP2000 model – column 79 shows that we have 1.92 inches to the right (this figure is showing the SAP2000 results); 1.85 inches in ABAQUS. We did two different ways and got very close answers. NIST is 5.5 inches to the left; revised to 6.2 inches – and why – because of some of the things I was telling. Understand? In my view.

Slide 82

So let's do a little comparative data:

For framed steel connections: UAF had accounted for them; NIST partially.

We have exterior steel framing connections included (springs) they did not. Exterior steel. I’m talking about the exterior walls, they had fixed. Remember?

Girder to column stiffener plates at column 79; Yes, no.

What about the floor composite with beams and not girders; Both of us considered that.

Composite with beams and girders; Yes but they did not.

Thermal expansion of the concrete to the deck? Yes but they did not.

Thermal conductivity and expansion for material properties. So what I did was go back and got the aggregate. Then I changed it to make sure that we knew what the thermal connectivity of the concrete would be – and the thermal expansion of that material if they actually made the concrete match to the additive type and so we can assume that they did not

Thermal expansion at column 79 with less than two inches.

Therefore based on our analysis column 79 temperatures were such that they could not have buckled under gravity loading – couldn’t have happened.

Slide 83

Did Building 7 collapse due to fires? No. This is based on our calculations. This contradicts the findings by the National Institute of Standards and Technology (NIST). The NIST approach. So that was what I viewed the real way it actually behaved. Not what you assumed, not what you do in terms of boundary conditions making things perhaps easier for yourself or whatever.

Slide 84

The concrete floor diaphragm stiffness is significant and even with no shear connectors, frictional resistance to thermal expansion is not trival.

We noticed that if you took those shear connectors out – which they argue that they're not there – take them out – I don't care. If they go away there is enough friction that without shear connectors on the beams it doesn't matter. It's not going to make a difference. So that's what we determine and we looked at it both ways

The thermal expansion of the concrete deck cannot be ignored and it is likely less than steel (the value is highly dependent upon the type of aggregate).

My research shows that you have thermal expansion of concrete as low as two – all the way to 12. Where as steel is about 6.5. So, it depends on the aggregate. So we were Dolemite aggregate – so we matched whatever we had here.

The research team evaluated fire by considering the air space below the beams in the space between the drop ceiling and the structural steel framing. We did that because a number of people felt like it was important.

The result is that a fire underneath will likely burn through the drop ceiling quickly and its resistance to heat transfer is likely not available to help.

The NIST vertical collapse was not consistent with that of the actual collapse.

I'm pointing out to you the progressive collapse picture that we looked at – that's what I'm saying here you understand what I’m saying. When you look at progression of the structure I don't think they look alike – something is different – totally different. I don't want that! I don't want that! That's not part of the game.

The NIST vertical collapse was not consistent with that of the actual collapse. The difference was primarily influenced by not modeling a significant portion of the structural framing connection details.There may be other issues, but certainly that had an effect. No doubt about that.

Slide 85

What’s next? We welcome your input. We welcome input from the world. We would want to be able to try to make sure that our findings are based on scientific facts and if there's a question, we're there to try to answer that and to make sure that our results are true and of value. We're providing a study to be peer reviewed. We are examining progressive collapse caused by various conditions such as failure of the substation level; shock waves imposed by falling debris from Towers one and two.

Whatever about the radiant heat that actually was imposed on the influence of that building structure by the Towers one and two when they heated up under the planes. I'm interested in examining building response for various columns removed;

We've already removed the inner core. I'm not sharing that with you, but it's very impressive what's going on. So then the question is what else is going on? We're examining issues related to the perimeter truss – there's about a lot of questions about, what, if they have a problem what would that mean to the structure.

And so, I think folks, that I'm done.

About the Author

Wayne co-authored a paper with John Wyndham and Michael R. Smith on the ethics, or lack thereof, of the official reports on the WTC building in a paper entitled, "Ethics and the Official Reports about the Destruction of the World Trade Center Twin Towers (WTC1 and WTC2) on 9/11: A Case Study," which was presented at the 2014 IEEE International Symposium on Ethics in Engineering, Science and Technology.

At the 2014 forum on Philosophy, Engineering and Technology (fPET 2014), session on Social Responsibility of Engineers, Wayne and Michael R. Smith presented "Neglecting Peer Review: A Case Study of Engineering Ethics and the Official Reports about the Destruction of World Trade Center Building 7 (WTC7) on 9/11," at Virginia Tech in Blacksburg, Virginia.

Additionally, he a coauthor of the paper, “The World Trade Center Analyses: Case Study of Ethics, Public Policy and the Engineering Profession” with Michael R. Smith, R. M. Korol in 2015. This paper was accepted by, SEFI, the European Engineering Association after a peer review process – and published in the SEFI 2015 conference proceedings. Unfortunately, upon arriving at the conference to present, his presentation was canceled and he was refused entry to the conference.